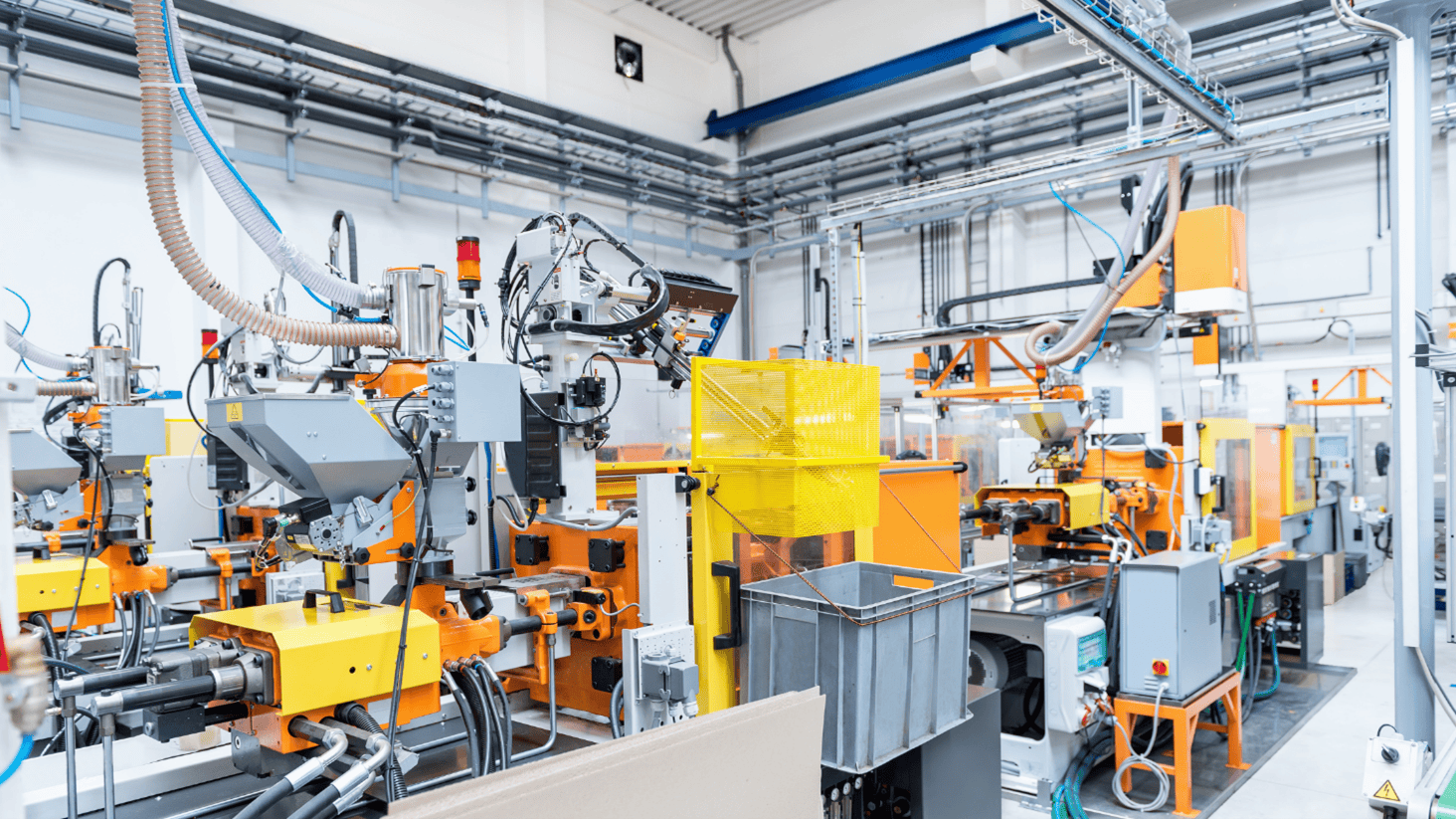

Complex component manufacturing demands machining capabilities that exceed traditional three-axis limitations. Industries requiring intricate geometries, compound angles, and multi-surface features increasingly rely on advanced machining technologies that deliver precision and efficiency in single-setup operations. The global precision machine market is expected to grow from $816.06 billion in 2025 to $2,142.96 billion by 2034, with five-axis technology leading this unprecedented expansion.

Manufacturing professionals recognize that achieving competitive advantage requires embracing technologies that reduce setup times, improve surface finishes, and enable production of previously impossible geometries. 5-axis machining technology represents the pinnacle of machining sophistication, enabling manufacturers to produce complex components with unmatched precision and efficiency.

Five-Axis Technology Overview

Five-axis machining technology incorporates two additional rotational axes beyond the standard three linear axes found in conventional machining centers. These additional axes, typically designated as A-axis and B-axis, enable cutting tools or workpieces to rotate and tilt during machining operations.

The fundamental advantage lies in the ability to approach workpieces from virtually any angle without requiring multiple setups or complex fixtures. This capability dramatically reduces production time while improving dimensional accuracy and surface finish quality across complex geometries.

Five-axis systems fall into two primary configurations. Table-table designs incorporate both rotational axes in the worktable assembly, providing unlimited rotation around both axes but limiting workpiece size due to clearance requirements. Head-table configurations combine one rotational axis in the spindle head with another in the worktable, offering different advantages for specific applications.

Market Growth and Industry Adoption

The precision machine market exhibits remarkable growth driven by increasing demand for complex components across multiple industries. Five-axis machining capabilities become essential as manufacturers face increasingly sophisticated design requirements and tighter tolerance specifications.

Aerospace component manufacturing drives significant adoption of five-axis technology. Aircraft engine components, turbine blades, and structural elements require complex geometries that traditional machining approaches cannot efficiently produce. The ability to maintain tool perpendicularity to complex surfaces enables superior surface finishes and dimensional accuracy.

Medical device manufacturing represents another major growth sector for five-axis technology. Custom implants, surgical instruments, and diagnostic equipment require intricate features and biocompatible surface finishes achievable through advanced machining approaches.

Automotive industry evolution toward electric vehicles creates new demands for precision components. Battery housings, electric motor components, and lightweight structural elements require sophisticated machining capabilities that five-axis technology provides.

Technical Advantages of Five-Axis Machining

Five-axis machining delivers multiple technical advantages that justify investment for manufacturers producing complex components. Recognizing these benefits helps justify technology adoption and optimize implementation strategies.

Single Setup Efficiency

The most significant advantage involves completing complex parts in single setups that would require multiple operations on three-axis equipment. Five-axis machines can machine nearly every visible surface, excluding the bottom or clamping area. This capability dramatically reduces production time and eliminates potential errors introduced during part repositioning.

Setup reduction translates directly into improved accuracy through maintained workpiece reference points. Once a part comes out of the machine, precise alignment is lost. By using the same “zero” or “home” location, feature-to-feature accuracy is improved significantly compared to multiple-setup approaches.

Labor costs decrease substantially when complex parts can be completed without operator intervention for part repositioning. Operators can focus on setup optimization and quality control rather than routine part handling operations.

Superior Surface Finishes

Five-axis technology enables optimal cutting tool orientation relative to machined surfaces throughout operations. The ability to maintain proper cutting angles produces superior surface finishes compared to three-axis approaches that may require compromise angles for complex geometries.

Tool deflection minimization occurs when cutting tools can be positioned closer to workpieces through optimal axis positioning. Using the rotating fourth and fifth axes, the part can be orientated to bring it closer to the cutting tool. If the part can get closer to the cutting tool, then the cutting tool can be shorter.

Shorter cutting tools reduce vibration and chatter that degrade surface finish quality. A shorter cutting tool is less susceptible to vibration at higher cutting speeds, which directly impacts surface finish and dimensional accuracy.

Enhanced Tool Life

Optimal cutting conditions throughout machining operations extend tool life significantly compared to compromised angles required in three-axis operations. Tool life and cycle time are improved as a result of tilting the tool/table to maintain optimum cutting position and constant chip load.

Consistent chip loads prevent tool wear patterns that occur when cutting conditions vary throughout part geometries. Maintained cutting speeds and feeds optimize material removal rates while preserving tool condition.

Heat dissipation improves when cutting tools maintain optimal angles relative to workpiece surfaces. Proper chip evacuation and coolant access become more effective with optimized tool positioning capabilities.

Application Sectors and Use Cases

Five-axis machining technology serves diverse application sectors, each presenting unique requirements and challenges. Understanding sector-specific needs enables optimal technology implementation and process development.

Aerospace Component Manufacturing

Aerospace applications demand exceptional precision and surface finish quality for components operating in extreme environments. Typical aerospace components produced by five-axis CNC tools include valves and turbine blades requiring precise execution on complex geometries.

5-Axis Machining Powering Precision Across Industries explores how advanced five-axis capabilities serve critical applications in aerospace, medical device manufacturing, and energy sectors that demand exceptional precision and complex geometries.

Turbine blade manufacturing exemplifies five-axis advantages through complex airfoil geometries requiring continuous surface transitions. Traditional machining approaches cannot maintain proper cutting angles throughout blade profiles, resulting in compromised surface finishes and dimensional accuracy.

Structural aerospace components benefit from five-axis capabilities when featuring complex ribs, lightening pockets, and mounting interfaces. Single-setup completion ensures dimensional relationships between features while reducing production time and potential error sources.

Medical Device Manufacturing

Medical device applications require exceptional surface finish quality and dimensional accuracy for components in direct patient contact. Medical instruments, implants, devices, and equipment parts must meet strict quality standards that five-axis technology readily achieves.

Custom implant manufacturing leverages five-axis capabilities to produce patient-specific geometries from biocompatible materials. Complex surface transitions and precise fit requirements demand machining capabilities that traditional approaches cannot efficiently provide.

Surgical instrument production benefits from five-axis precision in creating intricate features, sharp edges, and complex geometries required for minimally invasive procedures. Surface finish requirements for sterile environments demand superior machining capabilities.

Automotive Industry Applications

Automotive sector adoption of five-axis technology accelerates with industry evolution toward electric vehicles and advanced powertrains. The high throughput of five-axis equipment make these machines ideal for the low-mix, high-volume production needed for the automotive industry while maintaining the highest quality.

Engine component manufacturing utilizes five-axis capabilities for complex intake manifolds, cylinder heads, and turbocharger housings. These components feature compound curves and multiple machined surfaces requiring sophisticated machining approaches.

Transmission components benefit from five-axis precision in gear housing production, valve bodies, and complex internal geometries. Dimensional accuracy requirements for proper fit and function demand advanced machining capabilities.

Energy Sector Requirements

Oil and gas production industries require parts produced from extremely hard steels and exotic alloys using five-axis machines. Valve components, pump housings, and drilling equipment demand exceptional durability and precision achievable through advanced machining technology.

Renewable energy components including wind turbine parts and solar tracking mechanisms benefit from five-axis capabilities in producing large, complex geometries with tight tolerance requirements.

Nuclear industry applications require components meeting stringent quality standards for safety-critical applications. Five-axis precision enables production of reactor components and containment systems requiring exceptional dimensional accuracy.

Five-Axis Machine Types and Configurations

Recognizing different five-axis machine configurations helps manufacturers select optimal equipment for specific applications. Each configuration offers distinct advantages for particular workpiece types and production requirements.

Table-Table Configurations

Double rotary table designs provide both rotational axes in the worktable assembly. This 5-axis CNC design utilizes both an A-axis and a B-axis rotary table, enabling highly flexible part orientation. A key advantage lies in its ability to orient the part or fixture over a wide range of angles for advanced contouring and simultaneous machining operations.

Unlimited rotation capabilities enable complex part geometries without axis limit concerns. The worktable can rotate continuously around both axes, providing maximum flexibility for complex machining operations.

Workpiece size limitations occur due to clearance requirements around rotating table assemblies. Large parts may interfere with machine structure or encounter axis travel limits that restrict machining capabilities.

Head-Table Configurations

Head-table designs incorporate one rotational axis in the spindle head and another in the worktable. This configuration provides different clearance characteristics and may offer advantages for specific part geometries or production requirements.

Spindle head rotation provides tool orientation flexibility while maintaining workpiece stability. This approach may offer better rigidity for heavy cuts or large workpieces requiring substantial support.

Combined axis capabilities enable complex machining operations through coordinated movement of both head and table rotational systems. Programming complexity increases but machining flexibility expands significantly.

Horizontal vs Vertical Orientations

Machine orientation significantly influences accessibility, workpiece capacity, and operational characteristics. Vertical machines provide good accessibility for setup and operation but may have workpiece size limitations due to gravitational effects.

Horizontal configurations offer advantages for larger workpieces and may provide better chip evacuation characteristics. Tool changes and setup operations may require different considerations compared to vertical machine arrangements.

Workpiece mounting and clamping requirements vary between orientations and influence fixture design and operational procedures. Understanding these differences helps optimize machine selection for specific applications.

Programming and Operational Considerations

Five-axis programming presents significantly more complexity than three-axis operations but modern CAM software systems simplify many challenging aspects. Recognizing programming requirements and operational considerations confirms successful technology implementation.

CAM Software Requirements

Advanced computer-aided manufacturing software becomes essential for five-axis programming success. These systems must handle complex toolpath generation, collision detection, and post-processing for specific machine configurations.

Simulation capabilities prevent costly programming errors and machine crashes during initial program development. Virtual machining verification identifies potential problems before actual production operations commence.

Post-processor development ensures proper machine communication and coordinate system management throughout complex operations. Machine-specific post-processors optimize code generation for particular equipment configurations.

Collision Avoidance

Complex machine geometries and additional axes create numerous potential collision situations during five-axis operations. Comprehensive collision checking becomes essential throughout programming and operation phases.

Machine envelope verification ensures programmed operations remain within physical machine limitations. Software simulation identifies potential interference between machine components, workpieces, and fixtures.

Tool length and holder considerations become more critical in five-axis operations due to increased geometric complexity. Proper tool selection and holder design prevent collision issues while maintaining machining capabilities.

Coordinate System Management

Complex coordinate transformations occur throughout five-axis operations as workpiece orientation changes relative to machine axes. Recognizing coordinate relationships provides proper programming and dimensional accuracy.

Work coordinate systems must account for rotational axis positions and their effects on programmed coordinates. Proper coordinate system setup prevents dimensional errors and ensures accurate part production.

Tool center point management becomes more complex when multiple rotational axes influence cutting tool position and orientation. CAM software must properly calculate tool positions throughout complex operations.

Quality Control in Five-Axis Machining

Quality control systems for five-axis machining must address increased complexity while maintaining accuracy and efficiency. Advanced measurement techniques and process monitoring ensure consistent results throughout production operations.

Measurement Challenges

Complex geometries produced through five-axis machining require sophisticated measurement approaches. Traditional measurement methods may not adequately address compound curves and complex surface transitions produced by advanced machining techniques.

Coordinate measuring machines equipped with appropriate software and probing systems handle complex geometries effectively. Multi-axis CMM capabilities match machining complexity and provide comprehensive dimensional verification.

Surface finish measurement becomes more challenging on complex geometries but remains critical for many applications. Portable measurement systems may be required for large parts or complex surface access requirements.

Process Monitoring

Real-time process monitoring becomes more valuable as machining complexity increases. Tool wear monitoring, vibration analysis, and power consumption tracking provide early warning of potential problems.

Adaptive control systems can modify cutting parameters based on real-time feedback to maintain optimal performance throughout complex operations. These systems help maintain consistent quality and prevent tool breakage or part damage.

Statistical process control methods track performance trends and identify optimization opportunities. Historical data analysis enables continuous improvement of five-axis processes and quality systems.

Investment Considerations and ROI

Five-axis machining technology requires substantial capital investment but offers significant return potential for appropriate applications. Recognizing investment considerations and return calculations helps justify technology adoption.

Equipment Costs

Five-axis machining centers represent significant capital investments compared to three-axis equipment. Initial costs must be evaluated against productivity improvements and capability enhancements provided by advanced technology.

Software licensing and training costs add to initial investment requirements. CAM software, post-processors, and operator training represent ongoing expenses that must be factored into investment analysis.

Tooling and workholding systems for five-axis operations may require specialized equipment and higher initial costs. However, reduced setup requirements and improved productivity often justify these investments.

Productivity Improvements

Cycle time reductions through single-setup operations provide immediate productivity benefits. Complex parts requiring multiple setups on three-axis equipment can often be completed in single operations on five-axis machines.

Setup time elimination represents major cost savings for complex parts. The five-axis machine increases uptime, decreases human error, and eliminates the need for special fixtures, providing substantial operational benefits.

Improved part quality reduces rework and scrap costs while enhancing customer satisfaction. Superior surface finishes and dimensional accuracy achieve through five-axis technology provide competitive advantages.

Break-Even Analysis

Production volume requirements for justifying five-axis investment depend on part complexity and alternative manufacturing approaches. Simple parts may not justify advanced machining capabilities, but complex components show immediate benefits.

Labor cost considerations include reduced setup time, eliminated part repositioning, and improved operator efficiency. These factors significantly influence break-even calculations and investment justification.

Market opportunities enabled by five-axis capabilities may provide additional revenue sources that justify investment beyond immediate cost savings. New customer segments and applications become accessible through advanced machining capabilities.

Workforce Development and Training

Successful five-axis implementation requires comprehensive workforce development programs that address increased complexity and operational requirements. Investment in training ensures technology adoption success and maximizes return on equipment investments.

Operator Training Requirements

Five-axis operation complexity demands extensive operator training covering machine operation, programming basics, and troubleshooting procedures. Proper training prevents costly mistakes and ensures safe operation.

Hands-on training programs provide practical experience with complex operations and emergency procedures. Simulation-based training can supplement actual machine time while building operator confidence and competence.

Ongoing education keeps operators current with evolving technology and best practices. Regular training updates ensure continued improvement and adaptation to new challenges and opportunities.

Programming Expertise

CAM programming for five-axis operations requires specialized skills and extensive training. Investment in programming expertise pays dividends through optimized processes and reduced development time.

External training programs provide comprehensive education in five-axis programming techniques and best practices. Many CAM software vendors offer specialized training courses focused on five-axis applications.

Internal expertise development creates long-term capabilities and reduces dependence on external programming services. Cross-training initiatives ensure continuity and operational flexibility.

Ready to explore how five-axis machining technology can change your manufacturing capabilities? Contact our five-axis specialists to discuss your specific requirements and discover the competitive advantages advanced machining technology provides for complex component production.

To stay current with emerging developments in advanced machining capabilities, Future of 5-Axis Milling Machinery Advancements Opportunities provides detailed analysis of technological innovations and market opportunities that will define the next generation of five-axis manufacturing systems.

Industry Standards and Compliance Resources

Manufacturers implementing five-axis technology should reference comprehensive standards from ISO International Organization for Standardization which provides detailed specifications for machine tool accuracy and performance verification procedures. The Society of Manufacturing Engineers (SME) offers extensive resources on advanced machining techniques and best practices specifically applicable to five-axis operations and complex component manufacturing.

Frequently Asked Questions

What types of parts benefit most from five-axis machining? Complex components requiring multiple setups on three-axis equipment gain the most benefit from five-axis technology. Parts with compound angles, sculptured surfaces, deep cavities, or features on multiple faces see dramatic improvements in accuracy and production efficiency. Aerospace components, medical implants, and complex molds represent ideal applications where five-axis capabilities provide significant advantages over traditional machining approaches.

How much does five-axis technology increase production efficiency? Production efficiency improvements vary significantly based on part complexity, but typical gains range from 40-80% for complex components requiring multiple setups on three-axis equipment. Single-setup completion eliminates part repositioning time and reduces potential error sources. Setup time reduction, improved surface finishes, and enhanced dimensional accuracy contribute to overall efficiency improvements that often justify investment costs within 18-24 months.

What programming skills are required for five-axis operations? Five-axis programming requires advanced CAM software expertise and understanding of complex coordinate transformations. Programmers must master collision avoidance, toolpath optimization, and post-processing for specific machine configurations. Most successful implementations involve comprehensive training programs lasting several weeks and ongoing education to maintain proficiency with evolving technology and best practices.

How does five-axis machining affect tool selection and performance? Five-axis capabilities enable optimal tool orientation throughout machining operations, significantly improving tool performance and extending tool life. Shorter tools can be utilized due to improved accessibility, reducing deflection and vibration while improving surface finish quality. Tool selection becomes more critical due to increased geometric complexity, but proper selection yields substantial improvements in performance and cost-effectiveness.

What maintenance considerations apply to five-axis equipment? Five-axis machines require more sophisticated maintenance programs due to increased complexity and additional moving components. Regular calibration of rotational axes confirms continued accuracy, and advanced diagnostic systems monitor component condition. Preventive maintenance becomes more critical to prevent costly downtime, but modern machines incorporate extensive monitoring systems that predict maintenance requirements and optimize scheduling to minimize production disruption.